Component Introduction

Agricultural film extruder

Based on Jinming's years of experience in extrusion system design, combined with the processing characteristics of materials and the principles of rheology, we have continuously optimized the design through simulation and developed an extrusion system that is suitable for processing various different materials. The unique structure can effectively reduce the melt temperature and improve the adaptability of the extrusion system to raw materials such as PE and EVA. It has the characteristics of high output, low energy consumption, and good plasticization.

Agricultural film machine head

The mold head adopts an axial spiral core design, and the distribution channel adopts an O-shaped design to reduce retention and ensure fast switching. The inclined injection holes of each layer are nearly equal in length, and the main flow path is short. The melt is uniformly and symmetrically compounded through the distribution channel. Reasonable die design effectively avoids the adverse phenomena of frequent burning and melting of large die heads. The die head is forged from high-quality alloy steel and undergoes strict heat treatment, which is beneficial for refining grains, eliminating internal stresses in the metal, and improving the mechanical strength and service life of the die head. The mold head is processed by a German precision CNC machining center, producing thin films with excellent thickness uniformity.

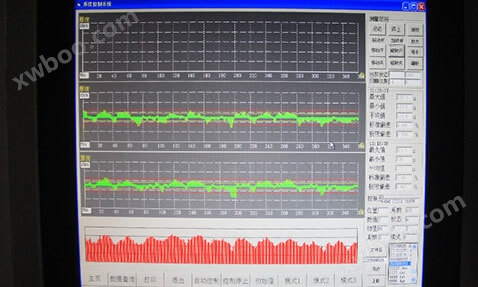

control system

Through digital communication networks, centralized control of key operating parameters such as temperature, speed, pressure, wind speed, traction, tension, and line speed of the entire machine has been achieved. At the same time, core parameters such as temperature, pressure, current, voltage, tension, speed, length, film thickness, and film thickness uniformity at each monitoring point are displayed and monitored in real time, with automatic alarm and self diagnostic functions.